Developing the Modular Programmable Logic Controller System With Custom 220VAC Optocoupler Sensor

Introduction

I led the design and development of a Modular Programmable Logic Controller system on a client’s specific request. This innovative project was created to control pump and heating systems at a basic level, offering modularity, programmability, and logical operation. The system is based on the ESP8266 microcontroller unit, which provides robust wireless communication and programmability. This system was produced in batch of 30 pieces and to this day all of them are working without any know problem.

Project Overview

Objectives

The main objective of the project was to create a versatile and expandable system capable of managing various devices and sensors in a heating and pump control setup. Key features include:

- Modularity: The system supports n-expandable modules connected via I2C and a custom communication protocol for an optocoupler sensor.

- Programmability: Users can configure the system to perform specific actions based on various operational modes.

- Logical Operations: The system provides binary outputs (0 or 1) based on the input conditions, making it suitable for logical control tasks.

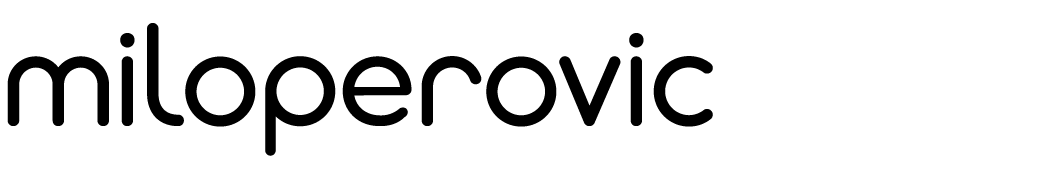

Key Components

- ESP8266 Microcontroller: The ESP8266 serves as the brain of the system, handling communication and control tasks. Its built-in WiFi capabilities allow for seamless integration with other devices and remote control.

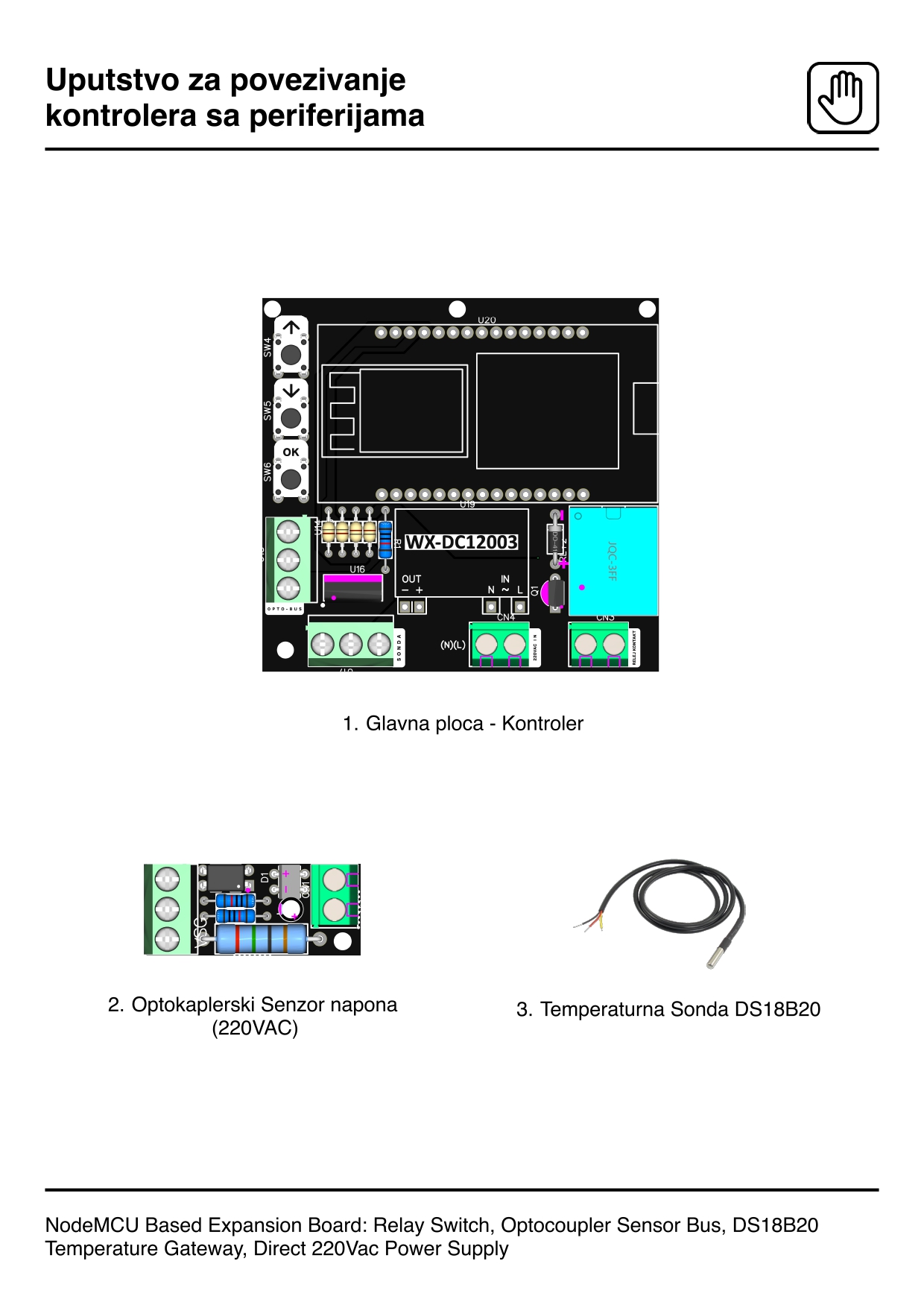

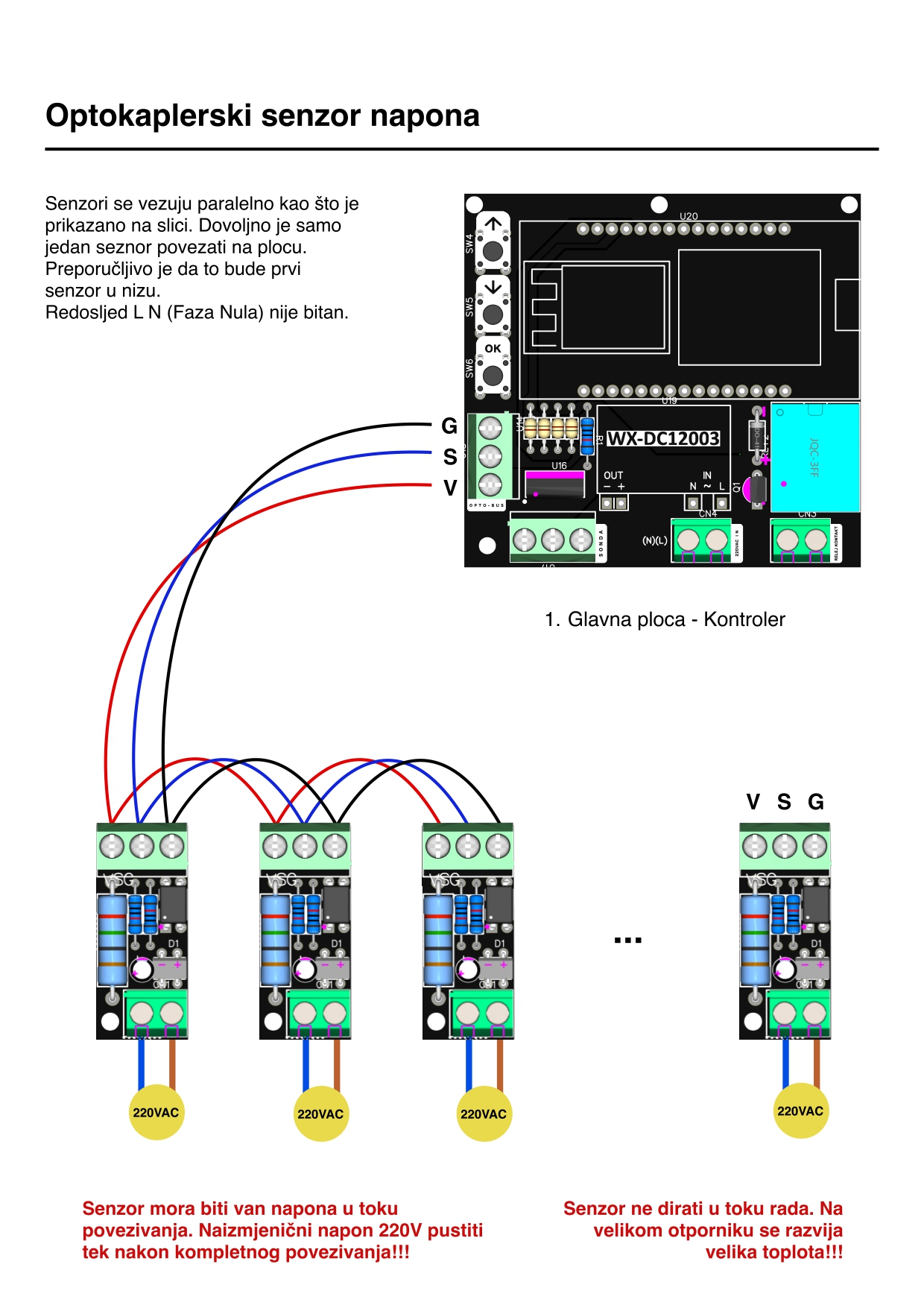

- Optocoupler Sensor: A crucial element of the project, the optocoupler sensor, reads signals from heat pumps, central heating stoves, or thermostats operating at 220VAC and converts them to a readable signal while maintaining electrical isolation. This ensures safe and reliable operation of the control system. Sensor is designed specific for this appliance.

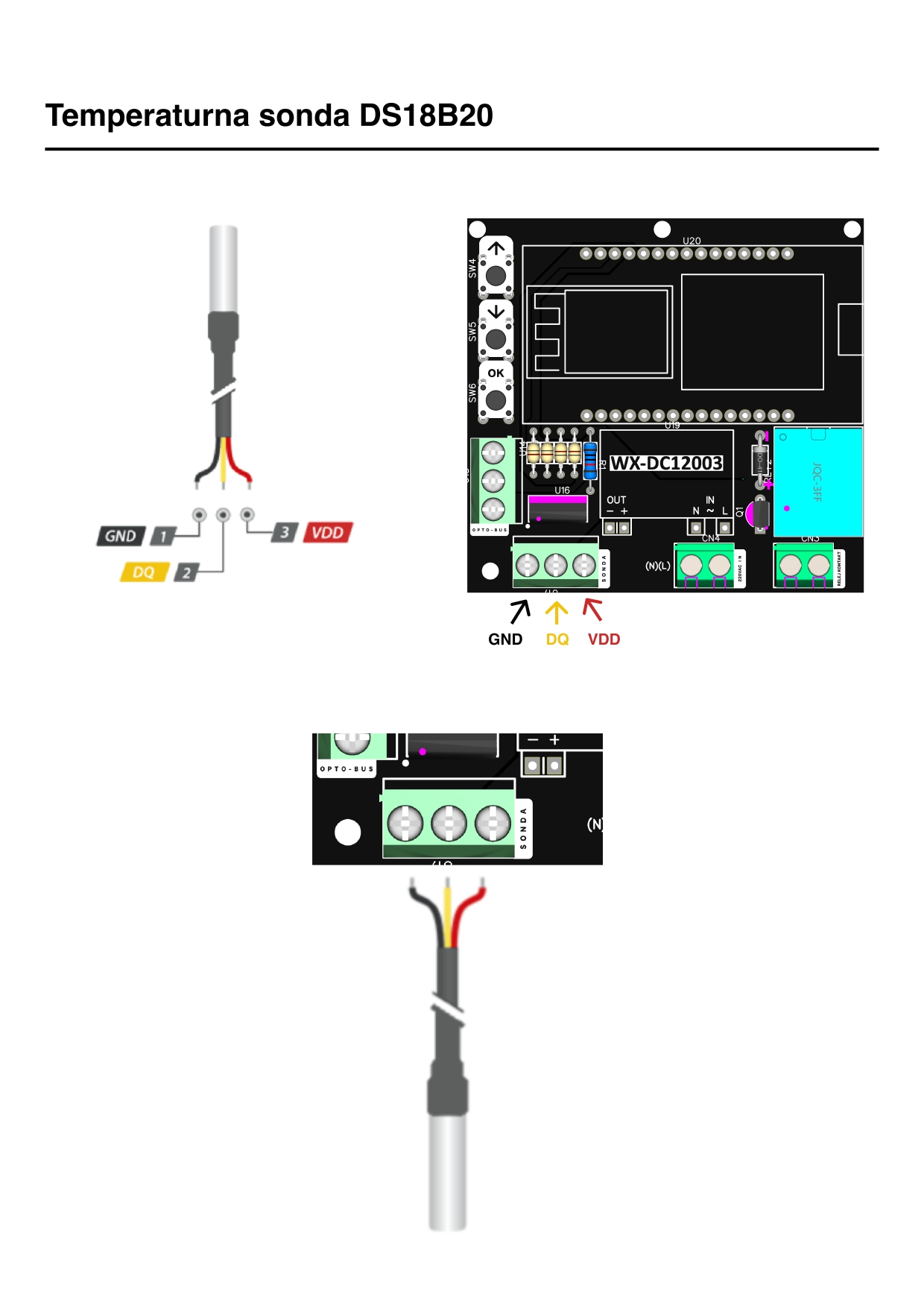

- Temperature Sensor (DS18B20): The DS18B20 temperature sensor provides precise temperature readings, which are essential for controlling heating systems.

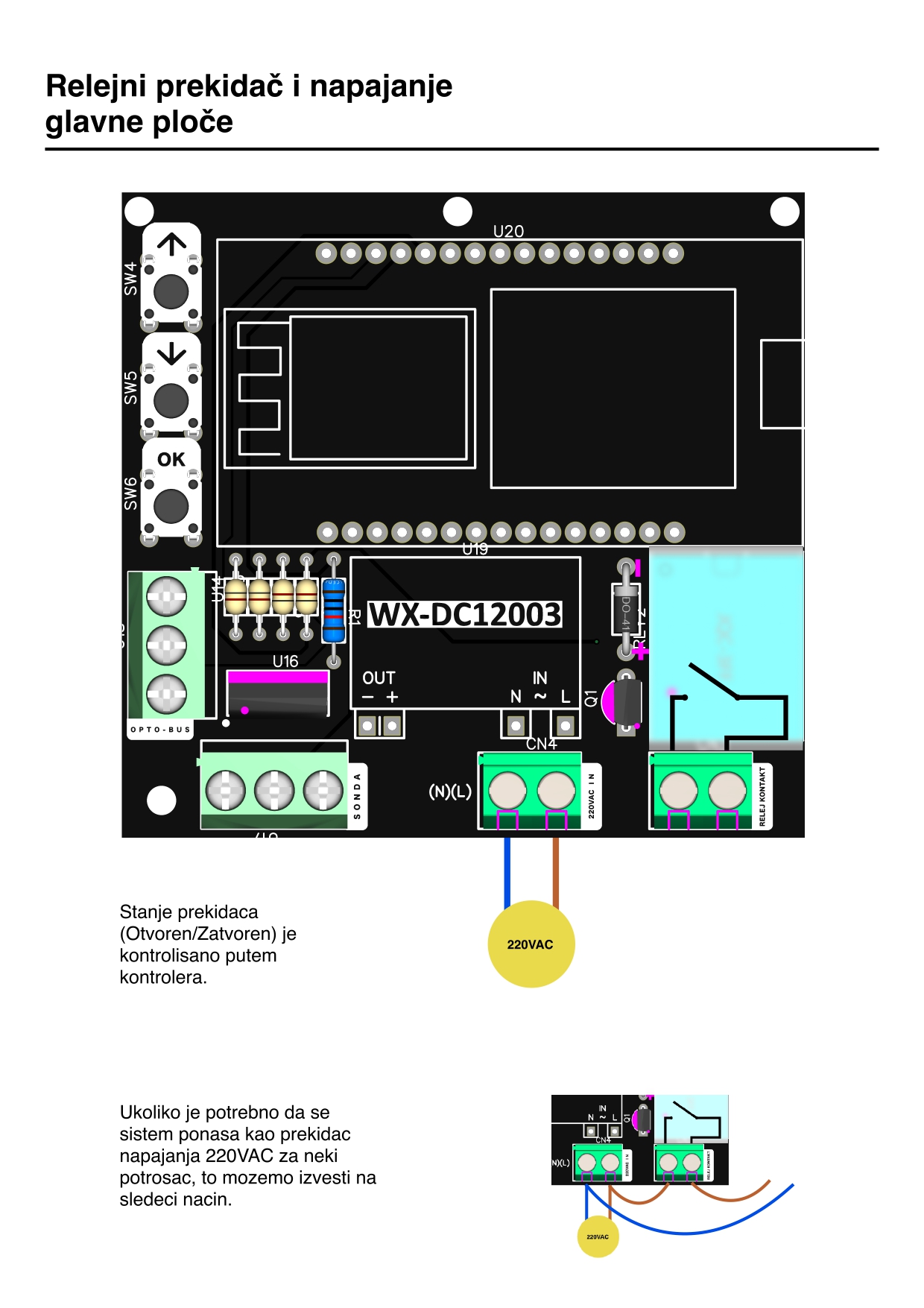

- Relay Switch: The relay switch is used to control the power supply to pumps or other devices, operating based on the logic defined in the system.

Operational Modes

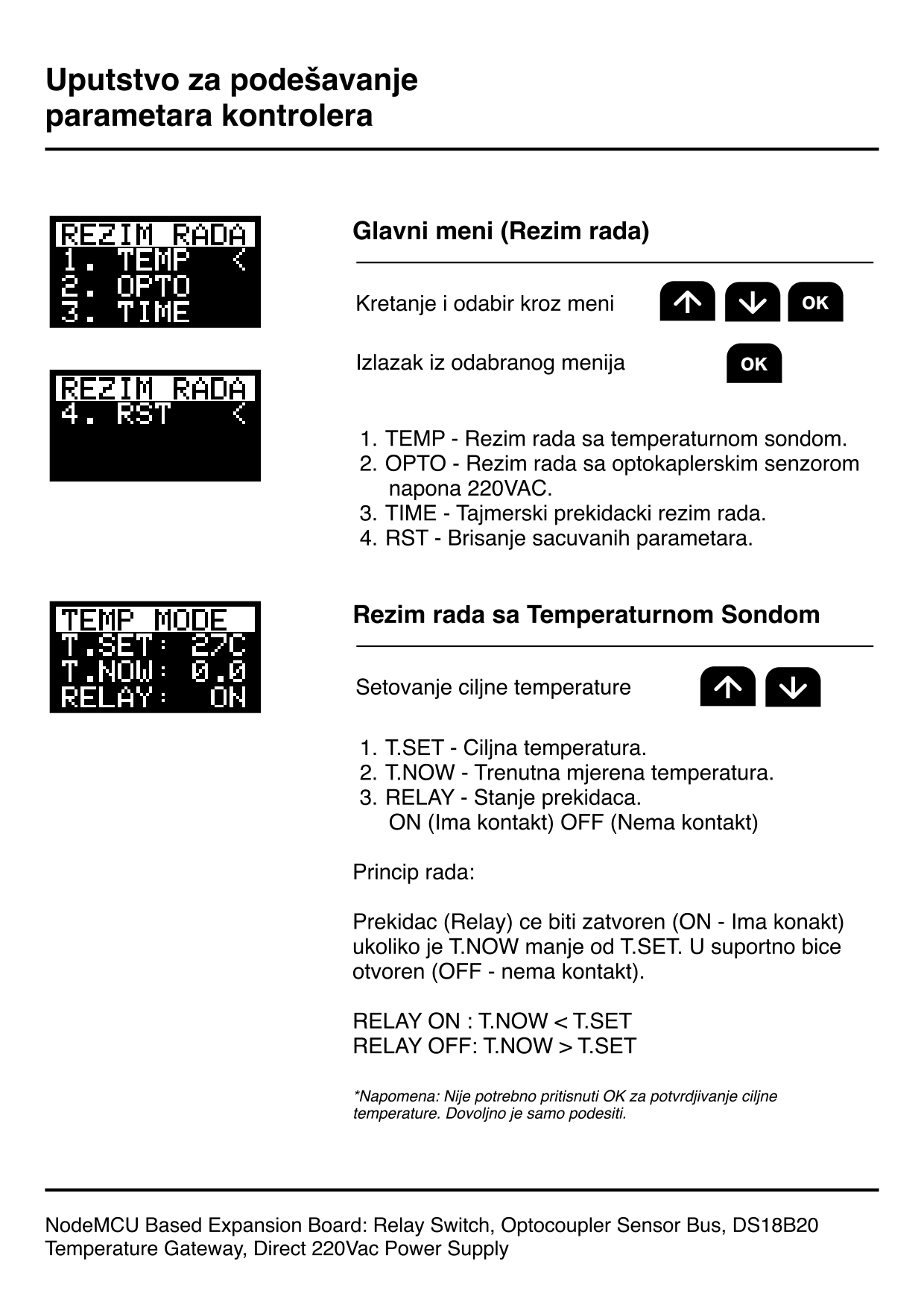

The system supports multiple modes of operation, which can be configured via the user interface:

- Temperature Mode (TEMP): The relay switch operates based on temperature thresholds set by the user. If the current temperature (T.NOW) is below the set temperature (T.SET), the relay will turn on.

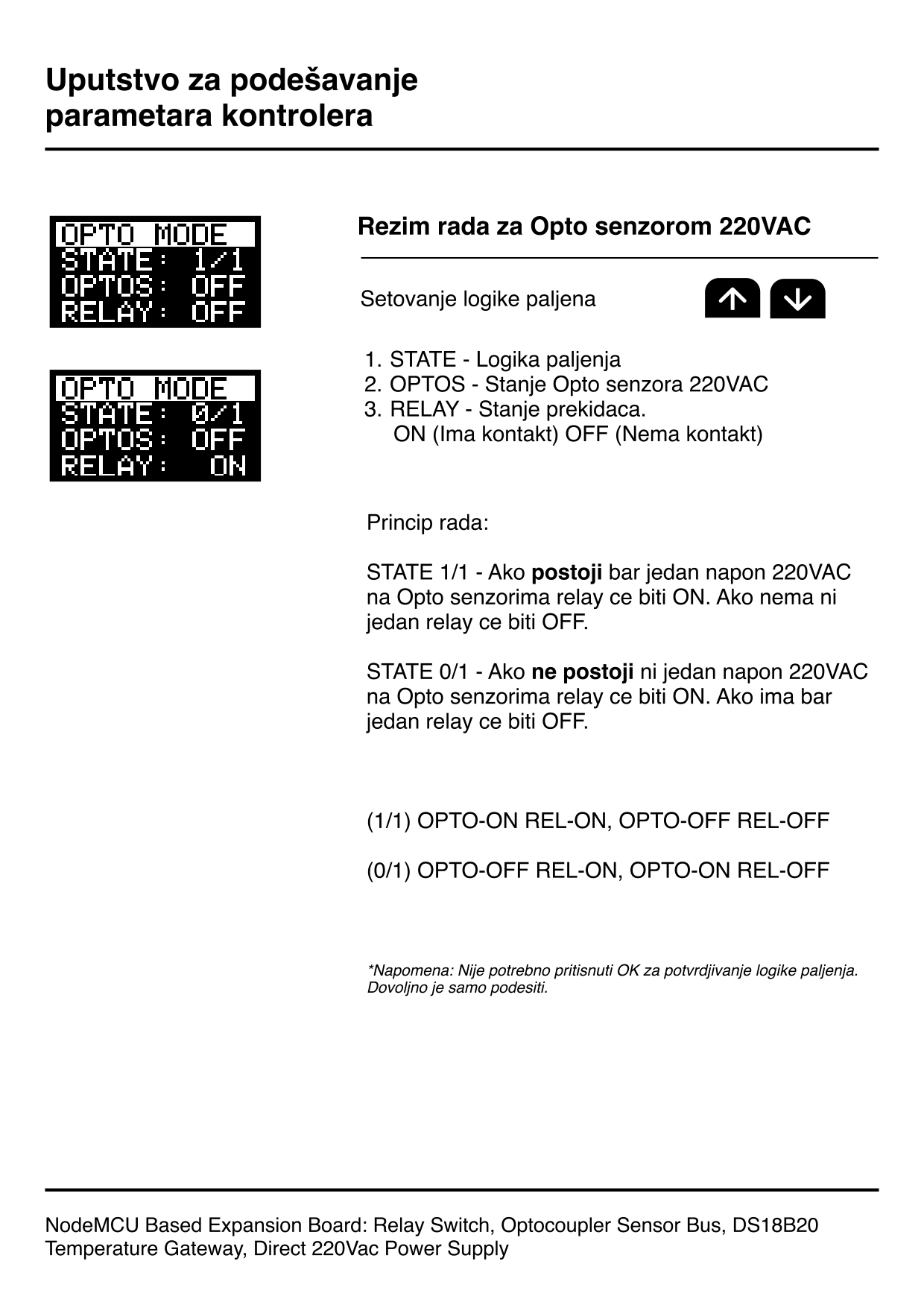

- Optocoupler Mode (OPTO): The relay switch operates based on the state of the optocoupler sensor. Users can set logic rules for the relay to turn on or off based on the presence of 220VAC signals.

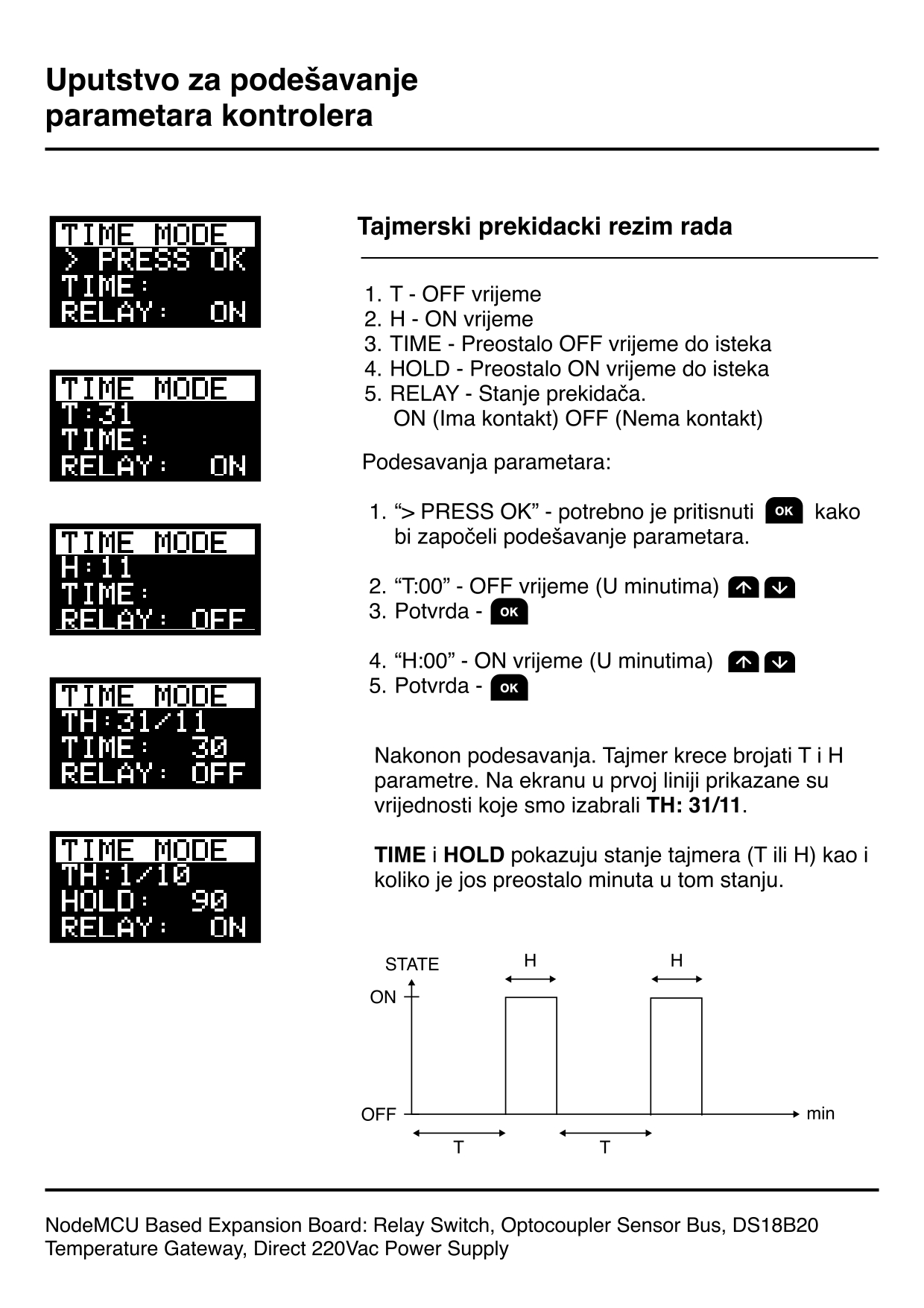

- Timer Mode (TIME): The relay switch operates on a timer, with configurable on and off periods.

User Interface

The user interface is designed for ease of use, allowing users to navigate through menus and set parameters with minimal effort. Key features include:

- Parameter Settings: Users can set temperature thresholds, timer values, and optocoupler logic directly from the interface.

- Status Monitoring: Real-time display of current temperature, relay status, and optocoupler sensor state.

- Data Persistence: All settings are saved, even in the event of a power loss, ensuring the system resumes operation with the same parameters.

Conclusion

The development of the Modular Programmable Logic Controller system showcases our ability to create sophisticated, flexible, and user-friendly control systems. By leveraging the capabilities of the ESP8266 microcontroller and integrating advanced sensor and communication technologies, we delivered a solution that meets the complex needs of modern heating and pump control systems.

This project highlights our expertise in both hardware and software development, as well as our commitment to delivering high-quality, reliable solutions. For more information on how we can assist with your technological projects, please feel free to contact us. Let’s work together to bring your vision to life!